Safe Home Fuel Storage: Fuel Types & Methods

Home storage of fuel is a necessity for homesteaders. Even if you are still on the grid, your truck, tractor, standby generator, etc. will still require fuel. I intend to offer appropriate methods of storage for LP gas, gasoline, diesel fuel, and kerosene. I will also offer some tips on safe fuel handling.

Fuel Types

LP Gas is one of the easiest fuels to store and also one of the most danger-ous. It is a highly versatile fuel which can be used to power internal combus-tion stationary engines, tractors, and other motor vehicles, as well as for cooking and heating. LP has two serious drawbacks: First, it must be stored under pressure to remain a liquid; any leak (which may not be visible) could leak away all of your fuel without your knowledge. Second, LP is only slightly heavier than air, and will dis¬perse at the exact ratio to produce an explosion. It will also “puddle” in low spots, waiting for an ignition source.

Gasoline has the advantage of being a liquid at room temperature. But it is probably the hardest fuel to store for any length of time. It has a high vapor pressure (which means it evaporates quickly) and will go stale in a few weeks if not chemically treated. It does have a fairly high ignition tem¬perature (about 1100° F) even though it does not need a large volume of heat to ignite. Stored gasoline must be treated with a BHT additive like Sta-Bil and protected from moisture if it is to be stored for any length of time.

Large quantities of gasoline make me nervous. I used to live on the water in southern Maryland, and was witness to several boat explosions and fires due to gasoline vapor in the bilges.

Kerosene is one of the easiest fuels to store, and is more versatile than most people think. It does not evapo¬rate as readily as gasoline and will remain stable in storage with no spe¬cial treatment. Many pre-1950 farm tractor engines were designed to run on kerosene, and diesels will run on kerosene if necessary. Kerosene stoves and refrigerators are also avail¬able and would definitely be prefer¬able to LP models from the safety standpoint.

Diesel fuel stores almost as easily as kerosene and is becoming more and more popular among the self suffi-cient. It is difficult to ignite intention-ally and almost impossible to ignite by accident. Two grades are available: #1 diesel which is old-fashioned yellow kerosene, and #2 diesel which is the same thing as #2 home heating oil. (You may see literature to the contrary, but #2 diesel is #2 heating oil. Period.) Diesel fuel presents its own unique storage problems: The first is that it is somewhat hygroscopic; that is, it will absorb moisture from the air. The second and related problem is sludge formation. Sludge is the result of anaerobic bacteria living in the trapped water and eating the sulfur in the fuel. Left untreated, the sludge will grow until it fills the entire tank, ruining the fuel. Stored diesel fuel should be treated with a biocide like methanol or diesel Sta-Bil as soon as it is delivered. Unique to #2 is the fact that some paraffin wax is dissolved in the fuel and will settle out at about 20° F, clogging the fuel filter. This “fuel freezing” may be eliminated by adding 10% gasoline or 20% kerosene to the diesel fuel. Commercial diesel fuel supplements are also available to solve the same problem. Diesel should be filtered before use.

Alcohol (Ethanol) is not commonly considered a storage fuel, but here is the data on it for those who distill their own. Alcohol is as hygroscopic as it gets, and must be stored in a sealed container to prevent moisture contamination. It is about as volatile as kerosene and presents the unique problem, when ignited, of burning with an almost invisible blue flame. It may be best to store the raw material for stilling the alcohol and producing the fuel as needed, rather than produc¬ing a large quantity and storing it.

Whatever fuel you store, it would be a good idea to monitor your fuel usage and plan your storage around a 90-day supply.

Safe Fuel Handling

Regardless of the fuel in question, all liquid fuels should be handled in the same matter as the most volatile, which is either gasoline or LP gas. Fuel should be stored in an isolated area, downhill and downwind from any other buildings. Fuel vapors are heavier than air, and will flow downhill. LP tanks should be left in the open and not enclosed in any way. Liquid fuel tanks can and should be stored in a well-ventilated building or open lean-to to prevent solar heating from evaporating the fuel. If the storage location is permanent, consider using a buried tank. If set below the frost line, temperatures are stable at 55° F or so, which will inhibit evaporation. The tanks will be safe from everything, including stray (or aimed!) gunfire, brushfires, and just about everything else except the EPA. If buried fuel tanks offend your sense of environmental responsibility, then consider an underground vault. This has the added advantage of being able to inspect the tanks from time to time. Regardless of the tank location, a dry chemical or C02 fire extinguisher should be hung on the outside of the building or near the pump. Any electrical fixtures should be “explosion proof” (sealed) and wired in sealed conduit to prevent fuel vapors from coming into contact with electrical sparks. Prohibit smoking or carrying of smoking materials within 50 feet of the fuel pumps. Electrical fuel pumps should have a heat sensitive shutoff to stop the pump in the event of fire. Always shut down the engine of the machine being fueled. Promptly clean up any spills. Last of all, be certain to use only the equipment that is approved for the fuel in question. (Some fuel pumps are approved for diesel only, and are unsafe to use for gasoline.)

Fuel Storage Methods

Liquid fuels use the same storage systems and will be covered as a group. LP gas is normally stored in pressurized tanks supplied by the LP dealer, and will be only briefly covered.

The most basic fuel storage system is the common portable fuel can. If you are still on the grid and have a job “off the property,” then this is a workable and economical method of fuel storage. A minimum of three cans will be required: one full at all times, one for use as needed, and one to be refilled at the first opportunity.

Rotation of the cans will ensure some amount of reasonably fresh fuel at all times. This storage system has the added advantage of portability in the event that the storage site must be abandoned. Use only approved containers, and use caution not to mix up containers. The standard color code for portable cans is blue for kerosene, red for gasoline, and yellow for diesel fuel. This is not cast in stone. Use whatever color scheme you like, but be consistent with it. Gasoline introduced into a diesel tank will make the diesel engine hard to start when hot. Gasoline in a kerosene heater will explode like a Molotov cocktail. Diesel #2 in a kerosene lamp will smoke and stink and soot up the globe. If you use all three fuels like we do, it seems that you will be filling a fuel can every time that you go out. Delivered fuel is much more convenient, and usually cheaper.

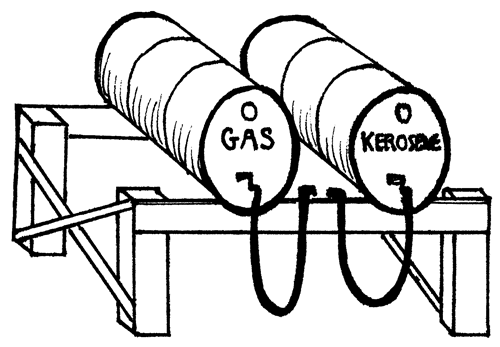

The next storage system is the 55¬gallon drum used with a hand pump or horizontally on a rack. This is a highly flexible storage system, as drums may be added as needed to suit individual requirements. Most fuel dealers have a 100-gallon minimum delivery, so at least two drums will be needed. You can even load one drum in your truck, drive to the service station and fill it, then bring it home and pump the fuel into your storage drum. Drums are also portable enough in the event that the storage site must be abandoned. The only disadvantages are the negligible cost of the drums and that the drums will eventually rust and leak.

We use drums for our kerosene and gasoline storage. Label each drum clearly if you are storing more than one type of fuel.

If you wish to store large quantities of fuel, then the built-for-the-purpose fuel tank is the system of choice. Tanks are available new in capacities from 100 to 10,000 gallons in above ground and underground types. Most commonly used here in the Northeast is the standard residential 275-gallon fuel tank. These are available new at plumbing and heating suppliers for about $150. Used tanks are usually available free for the hauling, including whatever fuel is in them. As a side note, an individual with a pickup truck and a reciprocating saw could make a fairly decent living removing old fuel tanks as homeowners change away from fuel oil to natural gas. This is about the dirtiest work available, and pays about $100 per tank. The removed tanks could be cleaned up, painted, and resold for $50 or more. I have accumulated about five or six tanks in the last few years without really looking for them.

Fuel dispensing is a matter of choice. An elevated tank needs only a valve and filter; gravity will do the rest. We prefer to use hand pumps for our kerosene and diesel tanks. Valves have been known to leak, and vandalism is an unfortunate reality of modern life—especially if the vandal elects to open the valve on a tank of gasoline and follow it up with a lit match. Hand pumps are safer, and they are more easily secured if the tank must be left unattended.

The Author’s System

My personal fuel storage system is a salvaged 275-gallon fuel tank with a hand pump and filter for our diesel fuel storage. Our principal tractor is diesel powered. We also use it to operate a PTO (power takeoff) generator for standby use. We use two or three 55-gallon drums for kerosene storage, with a lift pump for dispensing. (We rely on kerosene heaters to supplement our woodstove.) But, as I have a job “off the property,” and we have two old gasoline engine tractors, as well as a chainsaw, lawnmower, etc., the fuel can system works well for our gasoline supply. This is particularly suitable for us, as I feel uncomfortable about storing large quantities of gasoline.

Leave a Reply